Proper packaging of dangerous goods is not just a regulatory necessity. It’s a fundamental practice to ensure safety throughout the supply chain. If you’re a shipping company or a manufacturer, understanding and adhering to the rules of hazardous materials packaging can prevent accidents and ensure smooth operations. Here’s a friendly guide to help you get started.

Introduction to Dangerous Goods Packaging

When it comes to shipping dangerous goods, proper packaging is crucial for several reasons. Firstly, it prevents leaks and spills that could harm people and the environment. Secondly, it ensures compliance with international regulations, helping your business avoid fines and legal issues.

Lastly, meticulously packaged dangerous goods demonstrate your commitment to safety and responsibility, enhancing your company’s reputation.

Understanding the Basics

Before diving into the specifics of dg packaging, it’s essential to understand how dangerous goods are classified. The classification system is designed to categorise hazardous materials based on their specific risks. Here’s a brief overview:

- Class 1: Explosives

- Class 2: Gases

- Class 3: Flammable Liquids

- Class 4: Flammable Solids

- Class 5: Oxidizing Substances and Organic Peroxides

- Class 6: Toxic and Infectious Substances

- Class 7: Radioactive Materials

- Class 8: Corrosives

- Class 9: Miscellaneous Dangerous Goods

Each class has its own specific packaging requirements to ensure safety during transportation. Familiarise yourself with these classes to properly identify and package hazardous materials.

Key Rules for Safe Packaging

To safely package dangerous goods, adhere to the following essential rules and guidelines:

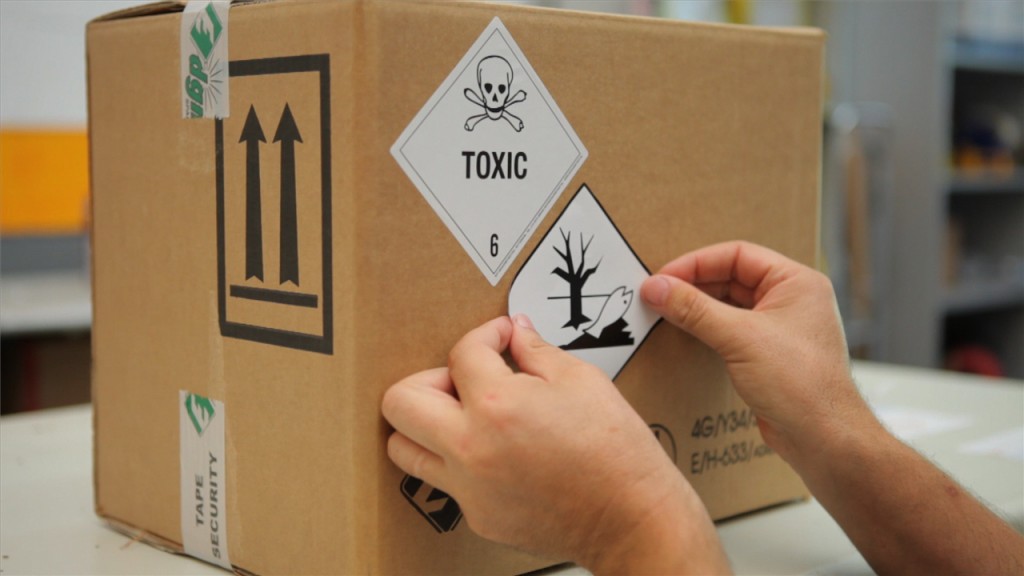

● Labeling and Marking

Proper labelling and marking are crucial in identifying the contents of the package. Use durable, weather-resistant labels that clearly display the hazard class and the UN identification number. Ensure that all markings and labels are easily visible and legible.

● Packaging Materials

Use packaging materials that are compatible with the type of hazardous goods you are shipping. This includes outer packaging that offers adequate protection and inner packaging that contains the dangerous substance securely.

Ensure that the packaging materials are approved and tested under relevant standards, such as those provided by the International Maritime Dangerous Goods (IMDG) Code or the International Air Transport Association (IATA).

● Documentation

Proper documentation is key to compliance and safety. Always include a comprehensive Dangerous Goods Declaration (DGD) along with your shipment. This document should detail the nature of the goods, their classification, and any special handling instructions. Ensure that all required documentation is accurately filled out and accompanies the shipment.

● Quantity Limits

Be aware of the quantity limits prescribed for particular hazardous materials. Exceeding these limits can result in increased risk and non-compliance with regulations. Always pack dangerous goods in accordance with the prescribed limits to ensure safety and legality.

● Secondary Containment

Consider secondary containment measures, especially for liquid hazardous materials. This involves using additional barriers, such as spill trays or absorbent liners, to prevent leaks in case the primary container fails. Secondary containment adds an extra layer of security, protecting both people and the environment.

Common Mistakes to Avoid

Even with the best intentions, mistakes can happen. Here are some common errors in dangerous goods packaging and tips to avoid them:

● Incorrect Labeling

One of the most frequent mistakes is incorrect or inadequate labelling. Always double-check that your labels are correct and follow the latest regulations.

● Incompatible Packaging Materials

Using materials that react with hazardous contents can lead to dangerous situations. Ensure compatibility by consulting the Safety Data Sheet (SDS) for specific guidelines.

● Insufficient Documentation

Incomplete or missing documentation can cause delays and fines. Be meticulous in preparing all required documents and ensure they are included in the shipment.

● Overfilling Containers

Overfilling can compromise the integrity of the container. Stick to prescribed quantity limits and ensure containers are filled correctly.

● Ignoring Secondary Containment

Neglecting secondary containment measures can result in spills and leaks. Always use secondary containment for added safety.

Conclusion

Proper packaging of dangerous goods is a vital aspect of shipping and manufacturing. Understanding the basics, following key rules, avoiding common mistakes, and learning from successful case studies, you can ensure the safe and compliant transportation of hazardous materials. Let’s make the world a safer place, one package at a time.

Remember, safety starts with you. Implement these guidelines and watch your business thrive while keeping everyone protected. Happy shipping!